Electric Power

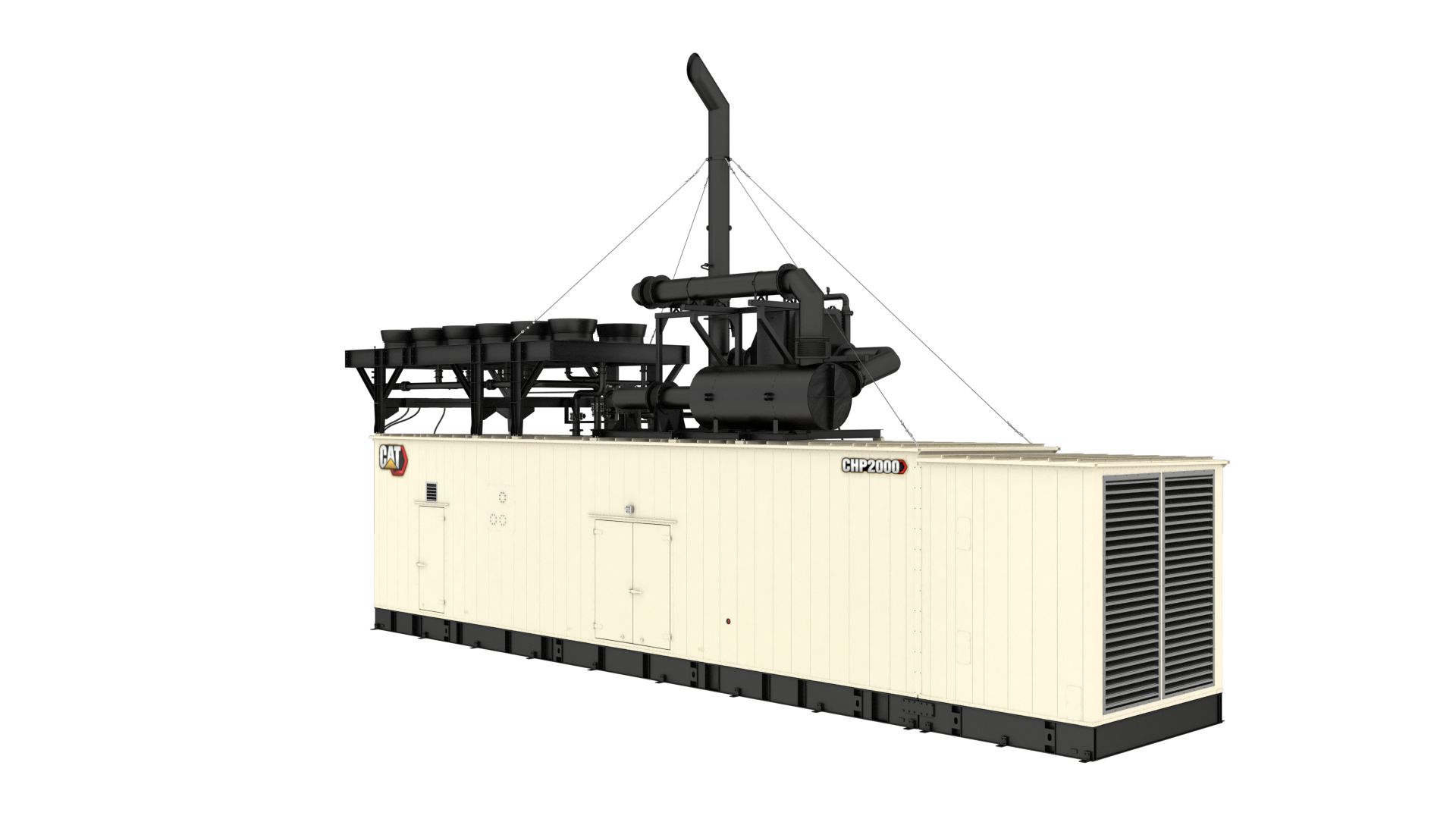

Cat G3516H Combined Heat and Power (CHP) Solution

-

Continuous Rating1982 ekW @ 1.0pf

-

Fuel TypeNatural Gas

-

Maximum Electrical Efficiency42.90%

-

Frequency60 Hz

Generator Set Specifications

- Continuous Rating

- 1982 ekW @ 1.0pf

- Fuel Type

- Natural Gas

- Maximum Electrical Efficiency

- 42.90%

- Frequency

- 60 Hz

- RPM

- 1500

- Frequency

- 60 Hz

Engine Specifications

- Engine Model

- G3516H

- Displacement

- 4765 in³

- Aspiration

- TA

- Bore

- 6.7 in

- Stroke

- 8.5 in

- Fuel System

- Electronic Fuel Control Valve

- Governor Type

- ADEM™ A4

- Compression Ratio

- 11.1

Generator Set Dimensions

- Length

- 716 in

- Width

- 155 in

- Height

- 467 in

- Dry Weight

- 40384 lb

- Weight

- 166600 lb

-

Engine

- G3520H, V20, 4-stroke-cycle, gas engine. Operates on 31.5 to 47.2 MJ/NM3 dry pipeline natural gas. Turbocharged Separate Circuit Aftercooled.

-

Control Panel

- On Package EMCP 4.3 Control Panel System Offers engine and generator monitoringand protection, voltage regulation with Cat IVRimproves transient response performance. Controls provide auto paralleling AGC-4 controller, load sharing, VFDcontrol, and primary generator protection for greaterversatility, package utilization and monitoring.

-

Air Inlet

- Package Mounted Air Cleaner with service indicator

-

Cooling

- ANSI/DN customer flange connections for JW inlet and outlet

- Engine driven water pumps for jacket water and aftercooler

- Jacket water and SCAC thermostats

- Standard cooling provides 40⁰C (104⁰F) ambient capability with 500mg/Nm3 NOx at 100% Continuous rating before derate, @ 500m

-

Containerized Module

- NSPS Factory Compilant, UL2200 Compilant and CSA / TSSA Sound attenuated 75 dB(A) @ 7 m (23 ft) Sound attenuated air intake louvers and lockable personnel doors with panic release LH and RH engine service doors integrated intocontainer side walls 3” ANSI flange customer fuel connection

-

Generator Controls And Protection

- Integrated crankcase ventilation system (CCV)and gas fuel train NFPA37 & CSAB149.3 with external fuel connections package utilization and monitoring.

-

Modes of Operation

- Provides for single unit stand-alone operation,island mode paralleling and load sharing withother power modules, and single unit-to-utilitymode paralleling for base load control

-

Lube Oil Make-Up System

- Integrated enclousre holding tanks: Oil makeup tank (50 gallon), Waste oil tank (300 gal / 2 oil changes), Fresh oil tank (500 gal / 2 oil changes + makeup) and oil level regulator. Low level annunciation

-

Exhaust

- Externally mounted exhaust system (muffler and heat exchanger)

- Dry exhaust manifolds, insulated and shielded

- Individual exhaust port and turbocharger outlet wired to Integrated Tmeperature Sensing Module (ITSM) with GECM providing alarms and shutdowns

- Center section cooled turbocharger with Cat flanged outlet

-

General

- Fire detection system

-

Circuit Breaker

- LSI Long-Time, Short-Time, Instantaneous Annunciator

- 5000A 3-Pole IEC Rated Circuit Breakers

- Rear-mounted

-

Fuel System

- Electronic fuel metering valve

- Throttle plate, 24V DC actuator, controlled by GECM

-

Fuel system

- Fuel system is sized for 31.5 to 47.2 MJ/NM3 dry pipeline natural gas with pressure of 10.2 to 34.5KPa to the engine fuel control valve

-

Ignition System

- Electronic Ignition System (controlled by ADEM A4)

- Individual Cylinder Detonation Sensitive Timing (DST)

-

Generator

- Double bearing SR5 1866 frame, brushless, form wound, 12-lead design, permanent magnet excited, three-phase, with Cat IVR, Class H insulation operating at Class F temperature. Stator and Bearing temperature monitoring and anti-condensation space heaters.

- SR4B

- Caterpillar's Digital Voltage Regulator (CDVR) with 3-phase sensing and KVAR/PF control

- Paint- Caterpillar Yellow except rails gloss black

- Busbar connections

- Crankshaft Vibration Damper and Guard

- Parts book

- Reactive droop

- SR5

- Anti-condensation space heater

- RH Service

- Operation and maintenance manuals

- Winding temperature detectors

-

Govrerning System

- ADEM A4 4-20mA (0-5VV) Speed Input

-

Air Inlet

- Mounting Brackets and Piping

- Air cleaner with precleaner

-

Circuit Breaker

- Frame Mounting

- MP- Frame 6 Pole Bottom Cable Entry

- No UV trip or package mounted CB Wiring

- 4000/5000A Neutral Current Transformer Automatic Selection

-

Control Panel

- Local alarm module

- Engine failure relay

- Remote PC Monitorring

- Remote Communications Module (PL1000T, PL1000E)

- Synchronizing module

- Local PC Monitorring

- Remote annuciator

- 16 Point/32 Light Annunciator, Shipped Loose

- Discrete I/O Module, 12 Digital Inputs, 8 'Form C' Relay

- Cat Connect: Ehternet, Satellite, Cell Telematics

-

Cooling

- Coolant level drain line with valves, fan with guard

- Inlet/Outlet connections

-

Exhaust

- Elbow

- Muffler and spark-arresting muffler with companion flanges

- Exhaust Expander

- Flexible Fitting

- Flange

- Oxidation catalyst

-

Fuel System

- Gas pressure regulator

- Gas shutoff valve 24V, ETR (Energized-To-Run)

- Gas Knockdown Regulator

- Fuel filter

-

Generator

- Manual voltage control

- Generator air filter

- Cable access box

- Medium and high voltage generators and attachment

- European bus bar

- Low voltage extension box

- Bearing temperature detectors

-

Starting/Charging

- Jacket water heater

- Battery with cables and rack (shipped loose)

- 24V starting motors

- 60A, 24V charging alternator (requires engine driven pumps)

-

General

- Tool set

- Digital diagnostic tool

- US AID Emblem

- Special paint order

- Cold-weather bundle including enclosure heaters and ventilation recirculation

- Fire suppression system

- Interior DC lighting system with automatic shutoff timer