Industrial

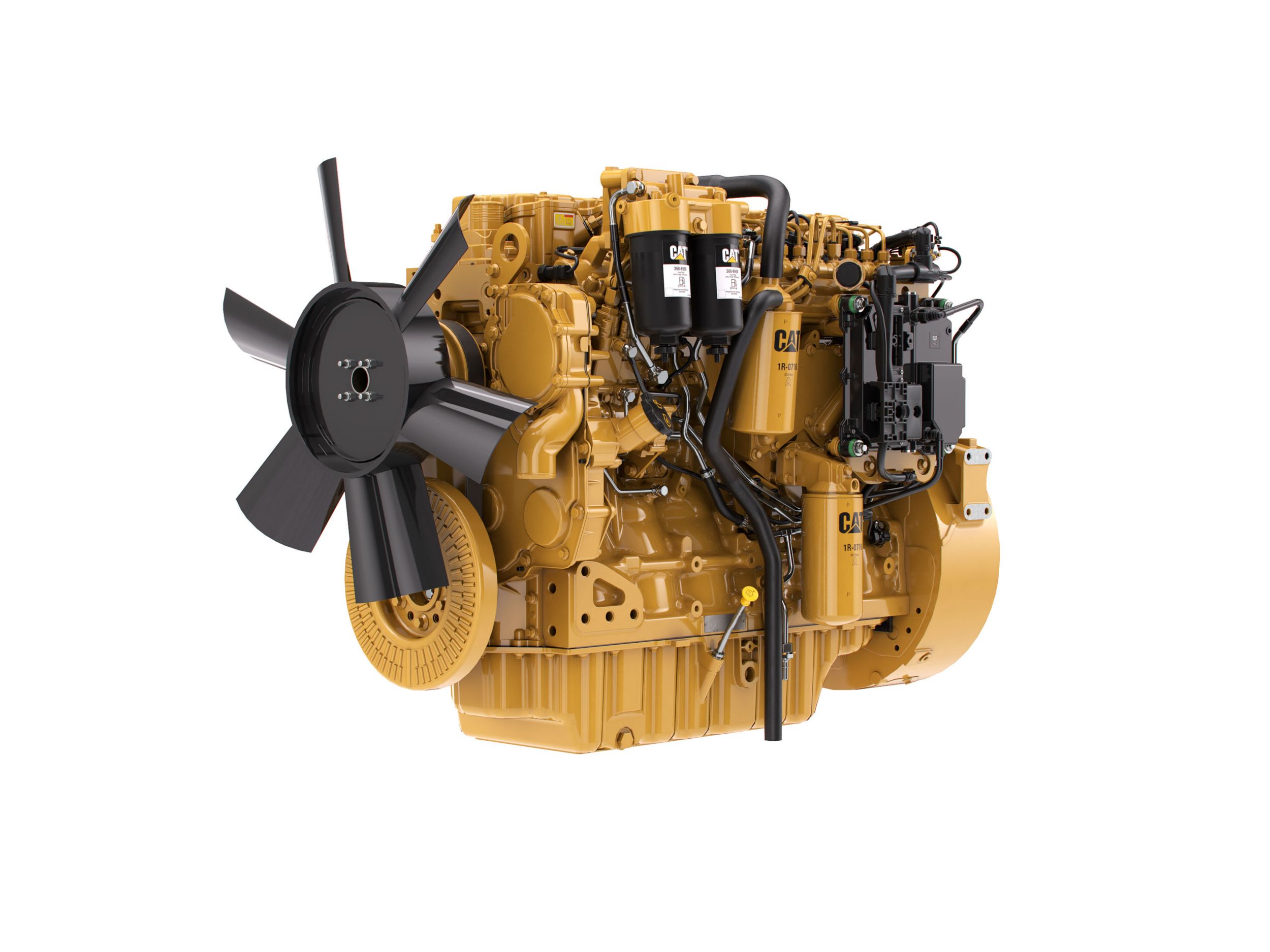

Cat?� C7.1 Diesel Engine

-

Minimum Power156.2 bhp

-

Maximum Power275 HP

-

Maximum Power275 hp

-

Maximum Power275.0 bhp

Power Rating

- Minimum Power

- 156.2 bhp

- Maximum Power

- 275 HP

- Maximum Power

- 275 hp

- Maximum Power

- 275.0 bhp

- Maximum Torque

- 774 lb-ft @ 1400 rpm

- Maximum Torque

- 774 lb-ft @ 1400 rpm

- Rated Speed

- 2200-2500 rpm

- Rated Speed

- 2200-2500 rpm

- Minimum Power

- 155.6 HP

- Minimum Power

- 155.6 hp

- Rated Speed

- 2200 rpm

Emission Standards

- Emissions

- China Nonroad III, U.S. EPA Tier 3 Equivalent, EU Stage IIIA Equivalent

- Emissions

- China Nonroad Stage III, Brazil MAR-1, UN ECE R96 Stage IIIA

- Emissions

- China Nonroad Stage III, Brazil MAR-1, UN ECE R96 Stage IIIA

General

- Engine Configuration

- In-Line 6, 4-Stroke-Cycle Diesel

- Engine Configuration

- In-Line 6, 4-Stroke-Cycle Diesel

- Engine Configuration

- In-Line 6, 4-Stroke-Cycle Diesel

- Bore

- 105 mm (4.1 in)

- Bore

- 105 mm (4.1 in)

- Bore

- 4.1 in

- Bore

- 4.1 in

- Stroke

- 5.3 in

- Stroke

- 5.3 in

- Stroke

- 135 mm (5.3 in)

- Stroke

- 135 mm (5.3 in)

- Displacement

- 427.7 in³

- Displacement

- 427.7 in³

- Displacement

- 7.01 L (427.7 in³)

- Aspiration

- Turbocharged Aftercooled (TA)

- Displacement

- 7.01 L (427.7 in³)

- Aspiration

- Turbocharged Aftercooled (TA)

- Aspiration

- Turbocharged Aftercooled (TA)

- Rotation

- Counterclockwise

- Rotation from Flywheel End

- Counterclockwise

- Rotation from Flywheel End

- Counterclockwise

- Aftertreatment

- -

- Aftertreatment

- -

Engine Dimensions - Approximate

- Length

- 36.6 in

- Length

- 36.6 in

- Width

- 26.3 in

- Width

- 26.3 in

- Height

- 32.2 in

- Height

- 32.2 in

- Weight

- 1115 lb

- Weight

- 1115 lb

- Height

- 835 mm (32.87 in)

- Length

- 929 mm (35.5 in)

- Weight

- 524 kg (1155 lb)

- Width

- 725 mm (28.5 in)

Engine Dimensions (Approximate. Final dimensions dependent on selected options)

- Length

- 929 mm (35.5 in)

- Width

- 725 mm (28.5 in)

- Height

- 835 mm (32.87 in)

- Weight

- 524 kg (1155 lb)

-

Air Inlet

- Standard air cleaners

-

Control System

- Full electronic control system, all connectors and wiring looms waterproof and designed to withstand harsh off-highway environments, flexible and configurable software features and well supported SAE J1939 CAN bus enables highly integrated machines

-

Cooling System

- Top tank temperature 108°C (226°F) as standard to minimize cooling pack size, 50:50 water glycol mix, detailed guidance on cooling system design and validation available to ensure machine reliability

-

Exhaust System

- Diesel particulate filter and regeneration system supplied, with a range of inlet and outlet options

-

Flywheels and Flywheel Housing

- Wide choice of drivetrain interfaces, including SAE1, SAE2 or SAE3 configurations

-

Fuel System

- Electronic high pressure common rail, ACERTTM Technology, innovative filter design to ensure maximum protection of the engine.

-

Lube System

- Wide choice of sumps for different applications

-

Power Take Off

- SAE A or SAE B flanges on left-hand side. Right- hand side twin PTO also available. Engine power can also be taken from the front of the engine on some applications, factory fitted compressors are also available.

-

General

- Paint: Caterpillar yellow, with optional colors available at request