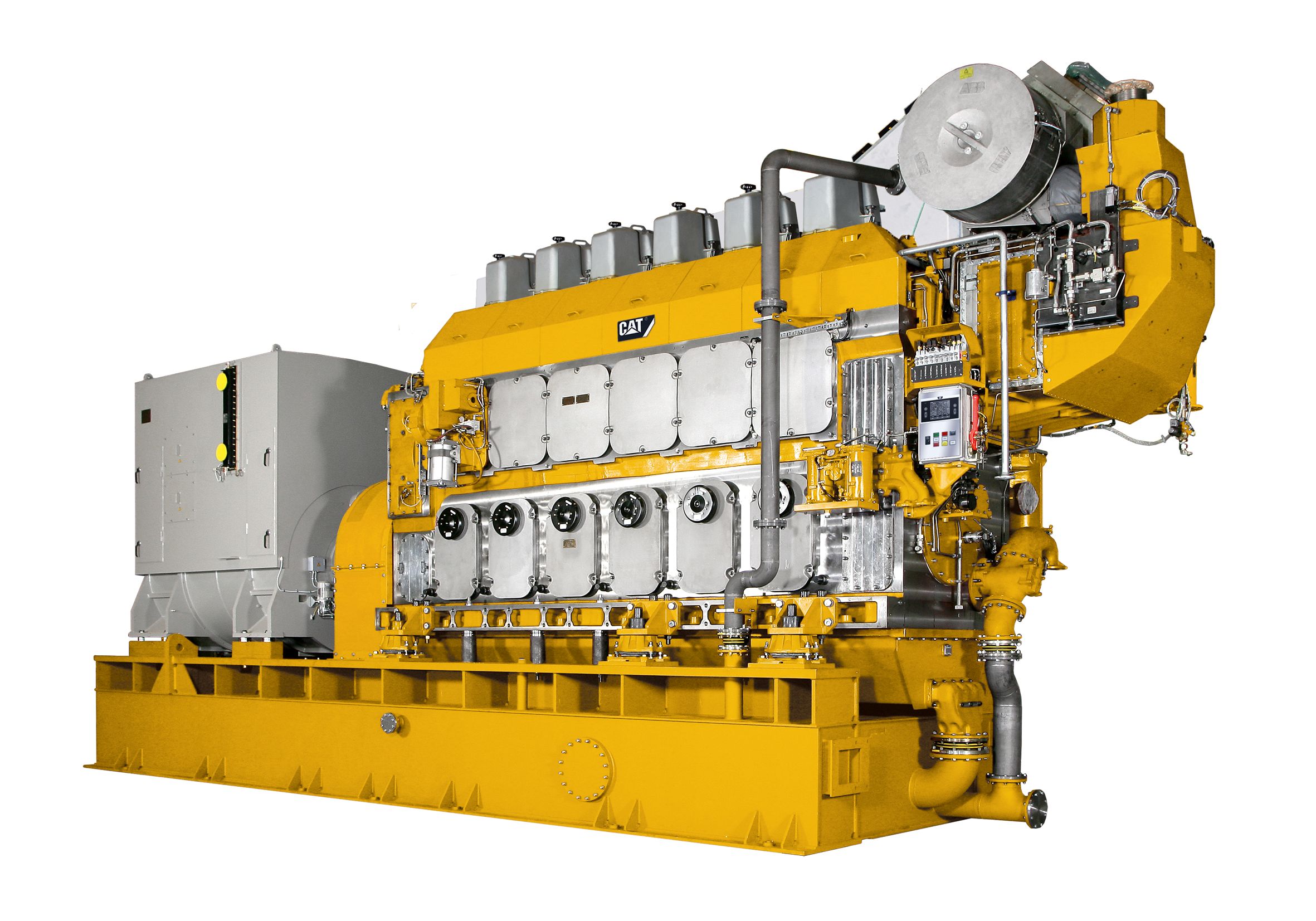

Offshore Drilling and Production Generator Sets

7CM46DF

-

Minimum Rating7640 kV·A

-

Maximum Rating8190 kV·A

-

EmissionsIMO Tier II

Engine Specifications

- Minimum Rating

- 7640 kV·A

- Maximum Rating

- 8190 kV·A

- Emissions

- IMO Tier II

-

Engine

- Motor-driven barring gear, fitted on engine

- Reversing contractor and pushbutton switch with cable

- Electronic speed setting equipment with actuator and speed pick-up

- Emergency shutdown equipment with pushbutton, separate, for manual emergency stop

-

Engine Indicators

- Gauge board with set liquid damped pressure gauges for: fuel, lubricating oil, fresh water, starting air, charge air

- On-engine thermometers for fuel, lubricating oil, fresh water and charge air

- Electric remote speed indicator

- Turbocharger and remote speed indicator

- Exhaust gas temperature indicator

-

Control System

- Manual control on engine, including: control panel with start/stop key, speed setting device, mechanical shutdown device, change over of control functions from engine to remote control

- Starting solenoid valve on engine, 24 V DC

- Separate electronic speed governor

-

Monitoring for Unattended Operation

- Pressure switches, mounted on engine

- Control Cabinet with housings for wall mounting, including: Protection equipment designed for automatic and manual stop input signals, starting interlock input signals, monitoring for the wire break of the input signal units and the emergency shutdown solenoid / Speed recording system for over speed, firing speed and minimum speed / Service hour counter

-

Starting Air System

- Separate non-return valve for the starting air pipe to the engine

-

Air Inlet System

- Air intake filter, separate

-

Gas System

- Double-walled gas piping to support an inherently safe engine room concept

- Leakage detection

- Gas valve unit

- Segmented gas detection system on request

-

Micro pilot fuel injection system

- Gear driven high pressure fuel pump and filter system with easy service access

- Reliability combined with service and maintenance simplicity, through individual ignition fuel injector and “in-cylinder head” integrated ignition fuel return pipes

-

Fuel System

- Circulating pump, separate, electric motor driven

- Duplex filter with differential pressure indication

-

Exhaust System

- Turbocharger at free end with transition nozzle (0 degree from the vertical and away from engine), with compressor cleaning device

- Expansion joint separate

-

Cooling System

- HT pump, separate on module, vertical design, electric motor driven

- LT pump, separate on module, vertical design, electric motor driven

- HT thermostat, not powered and separate on module

- Engine preheating equipment, fitted on base frame

-

Lube System

- Plate cooler, separate on module

- Force pump, fitted on engine

- Pre-Lubrication pump, separate on module, electric motor driven

- Automatic back flushing filter, fitted on engine

- Duplex filter with differential pressure indication, separate on module

- Pressure control valve, fitted on engine

- Thermostats, not powered, separate on module

-

Connection Parts-Engine

- Set of connecting parts between flange coupling and flywheel

- Flexible flange coupling between engine and generator

- Base frame with flywheel guard and incorporating lube oil sump tank, for engine and generator

- Mounting of engine and generator on the base frame

- Set of bonded rubber rails for resilient mounting of the base frame

- Set of flexible pipe connection

-

Tools

- Set of tools for the engine including hydraulic tightening tools and nozzle tester

- Set of tools for turbocharger

- Inside micrometer for cylinder liners

- Ruler for cylinder liner

-

Spare Parts

- Set of engine spare parts for unrestricted operation

- Set of spare flexible pipe connections

-

Monitoring for Unattended Operation

- Start/stop logic, controlled by engine automatic start

- Optional alarm system, cassette type, designed for alarm inputs for the engine including exhaust mean-value monitoring equipment as well as alarm inputs for the propulsion plant

- Optional group alarm panel for the bridge and with optional and acoustic alarm equipment

-

Starting Air System

- Air bottle, separate

-

Exhaust System

- Separate silencer and spark arrester, unlagged 35 dB(A)