Cold Planer

PM620 Cold Planer

-

Milling Width79.1 in

-

Rated Power636 hp

-

Operating Weight73480 lb

-

Maximum Milling Depth13 in

Cutting System

- Milling Width

- 79.1 in

- Maximum Milling Depth

- 13 in

- Rotor Speeds

- 100 / 109 / 118 rpm

- Number of Bits

- 178

Power Train

- Rated Power

- 636 hp

- Engine

- Cat C18

- Maximum Travel Speed

- 3.7 mile/h

- Maximum Milling Speed

- 328 ft/min

- Global Emissions

- Tier 4 Final / Stage IV

Weights

- Operating Weight

- 73480 lb

- Transport Weight

- 64882 lb

- Operating Weight

- 73260 lb

Dimensions

- Operating Width

- 9.15 ft

- Operating Length

- 47.64 ft

- Operating Width

- 10.2 ft

- Height

- 13.29 ft

- Maximum Truck Clearance

- 15.94 ft

- Minimum Right Cutting Radius

- 6.56 ft

- Minimum Left Cutting Radius

- 6.56 ft

- Conveyor Swing

- 60 degrees from center

- Transport Length

- 40.78 ft

- Transport Width

- 8.14 ft

- Transport Height

- 9.84 ft

- Transport Length

- 40.79 ft

- Transport Width

- 8.20 ft

- Transport Height

- 9.84 ft

Service Refill Capacities

- Fuel Tank

- 288.1 gal

- Diesel Exhaust Fluid

- 12.2 gal

- Cooling System

- 22.1 gal

- Engine Oil

- 16.9 gal

- Hydraulic Tank

- 29.4 gal

- Water Spray System Tank

- 898.2 gal (US)

- Cooling System

- 22.5 gal (US)

- Diesel Exhaust Fluid

- 12.4 gal (US)

- Engine Oil

- 17.2 gal (US)

- Fuel Tank

- 292.7 gal (US)

- Hydraulic Tank

- 29.9 gal (US)

-

OPERATOR ENVIRONMENT

- Ground control keypads

- Single high-resolution LCD touchscreen display

- 12-volt power receptacle

-

CONVEYOR

- Grease tensioner

- Material removal boost feature

-

CAT CONNECT TECHNOLOGY

- Remote troubleshoot capability

- Cat Product Link

- Cat GRADE

-

ROTOR SYSTEM

- Automatic plunge-cut

- Automatic transition feature

- Obstacle jump

- Three cutting speeds

-

POWERTRAIN

- Auto engine idle control

- High capacity cooling system

- Dual propel pumps

- Automatic load control

-

HYDRAULIC SYSTEM

- Dual pump hydraulic propel system

- Traction control

-

SERVICE AND MAINTENANCE

- Sampling ports for Scheduled Oil Sampling (S·O·S℠)

- Power hood

- Platform-level engine oil dipsticks

- Rotor chamber water spray system

- Air compressor

- Accessory drive system

- 3400 L (898 gal) onboard water tank

- Side water fill valve

-

SAFETY AND SECURITY

- Platform handrails

- Signaling/warning horn

- Wide-dispersion LED work lights

-

OPERATOR ENVIRONMENT

- Dual high-resolution LCD touchscreen displays

- Hydraulically folding canopy with LEDs

- Air-ride suspension seats

- Windscreens

-

CAT CONNECT TECHNOLOGY

- Inboard ski

- Sonic sensor (averaging or string line)

- Ground level grade controls and displays

-

CONVEYOR

- Dust abatement system

- Remote camera (loading conveyor)

-

ROTOR SYSTEM

- System K Rotor - Course (25 mm)

- System K Rotor - Course (18 mm)

- System K Rotor - Standard (15 mm)

- System K Rotor - Fine (8 mm)

- System K Rotor - Micro (6 mm)

- System H Rotor - Micro (6x2 mm)

- Diamond bits

- Bit bucket trays

- Pneumatic bit removal tool

- Tool holder extractor

- Rotor turning device with pendant control

-

POWERTRAIN

- CE certificate

-

HYDRAULIC SYSTEM

- Water tank transfer pump

- Fuel transfer pump

-

SERVICE AND MAINTENANCE

- High pressure washdown

- Low pressure washdown

- Additional spray bars

- Remote Flash

-

SAFETY AND SECURITY

- Perimeter LED strip lights

- Magnetic LED work light

- Warning beacon (fixed or magnetic mount)

- Truck signal lights

- Remote camera (rear, front, magnetic mount)

-

$315,000 2022 Cat 330-07

-

$315,000 2022 Cat 33007

-

$299,900 2021 Cat 330-07

-

$100,000 2019 Cat 972MXE

-

$99,950 2017 Cat CS44B

-

Browse All Used Equipment Inventory

View More

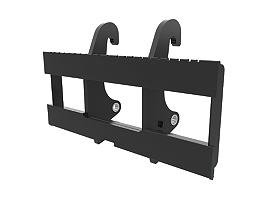

Forks: 1524mm (60in) Log & Lumber Fork; Fusion™

Forks: 1524mm (60in) Log & Lumber Fork; Fusion™  Forks: 2298mm (90in) Logging Forks

Forks: 2298mm (90in) Logging Forks  Forks: 1566 mm (62 in) Pallet Fork Carriage

Forks: 1566 mm (62 in) Pallet Fork Carriage  Forks: 1550 mm (61 in) Pallet Fork Carriage

Forks: 1550 mm (61 in) Pallet Fork Carriage