Underground - Hard Rock

R1300G Underground Mining Loader

-

Engine ModelCat® 3306B DITA

-

Engine ModelCat® 3306B DITA

-

Rated Power2200.0 rpm

-

Rated Power2200 r/min

Engine

- Engine Model

- Cat® 3306B DITA

- Engine Model

- Cat® 3306B DITA

- Rated Power

- 2200.0 rpm

- Rated Power

- 2200 r/min

- Gross Power

- 165 HP

- Engine Power

- 157 HP

- Bore

- 4.75 in

- Net Power

- 141.0 hp

- Stroke

- 6 in

- Net Power

- 141.0 hp

- Displacement

- 640.75 in³

- Net Power

- 141.0 hp

- Note

- Power ratings apply at a rated speed of 2,200 rpm when tested under the reference conditions for the specified standard.

- Note

- All rating conditions are based on ISO/TR14396:2002, inlet air standard conditions with a total barometric pressure of 100 kPa (29.5 in Hg), with a vapor pressure of 1 kPa (0.295 in Hg), and 25° C (77° F). Performance measured using fuel to EPA specific

- Note

- Engine derate will commence at an altitude of 4500 m (14,763.7 ft).

- Bore

- 4.75 in

- Stroke

- 6.0 in

- Displacement

- 640.75 in3

- Gross Power

- 165.0 hp

- Engine Power

- 157 HP

Engine Power

- Engine Power

- 157 HP

Operating Specifications

- Nominal Payload Capacity

- 14991 lb

- Rated Payload

- 14991 lb

- Nominal Payload Capacity

- 14991.0 lb

- Gross Machine Mass

- 65482 lb

- Static Tipping Load

- 45360 lb

- Static Tipping Load

- 39397 lb

- Breakout Force

- 26504 lb

- Gross Machine Mass

- 61178.0 lb

Weights

- Empty

- 46187.0 lb

- Empty

- 45691 lb

- Operating Mass

- 45691 lb

- Operating Mass

- 16810 lb

- Operating Mass

- 28881 lb

- Operating Mass

- 60682 lb

- Operating Mass

- 41105 lb

- Operating Mass

- 19577 lb

- Note

- *Calculated weights.

- Loaded

- 61178.0 lb

- Loaded

- 60682 lb

- Empty

- 17967.0 lb

- Empty

- 28220.0 lb

- Loaded

- 41050.0 lb

- Loaded

- 20128.0 lb

- Empty

- 16810 lb

- Empty

- 28881 lb

- Loaded

- 41105 lb

- Loaded

- 19577 lb

Transmission

- Forward

- 2.8 mile/h

- Forward

- 4.8 mile/h

- Forward

- 9.3 mile/h

- Forward

- 16.3 mile/h

- Reverse

- 2.8 mile/h

- Reverse

- 4.8 mile/h

- Reverse

- 9.2 mile/h

- Reverse

- 14.3 mile/h

- Forward 1

- 3.1 mph

- Forward 2

- 5.6 mph

- Forward 3

- 10.6 mph

- Forward 4

- 14.9 mph

- Reverse 1

- 3.1 mph

- Reverse 2

- 5.0 mph

Hydraulic Cycle Times

- Raise

- 5 s

- Dump

- 2 s

- Lower

- 2.3 s

- Total Cycle Time

- 9.3 s

Bucket Capacities

- Dump Bucket

- 3.2 yd³

- Dump Bucket

- 3.7 yd³

- Dump Bucket

- 4.1 yd³

- Dump Bucket

- 4.4 yd³

- Ejector Bucket

- 3.1 yd³

- Bucket Capacities

- 2.5-3.4 m³ (3.2-4.4 yd³)

Turning Dimensions

- Outside Clearance Radius

- 226.0 in

- Inner Clearance Radius

- 111.2 in

- Outside Clearance Radius

- 225.1 in

- Inner Clearance Radius

- 111.2 in

- Axle Oscillation

- 10°

- Articulation Angle

- 42.5°

- Articulation Angle

- 42.5°

Tires

- Tire Size

- 17.5 × R25

- Tire Size

- 17.5 × R25 VSMS

Service Refill Capacities

- Engine Crankcase

- 6.6 gal (US)

- Transmission

- 11.9 gal (US)

- Hydraulic Tank

- 23.2 gal (US)

- Cooling System

- 17.7 gal (US)

- Front Differential and Final Drives

- 10 gal (US)

- Rear Differential and Final Drives

- 11.1 gal (US)

- Fuel Tank

- 77.9 gal (US)

- Cooling System

- 17.7 gal

- Engine Crankcase with Filter

- 6.6 gal

- Front Differential and Final Drives

- 10.0 gal

- Fuel Tank

- 77.9 gal

- Hydraulic Tank

- 23.2 gal

- Rear Differential and Final Drives

- 11.1 gal

- Transmission

- 11.9 gal

Standards

- Standards

- ROPS/FOPS Certified Cab

- Brakes

- ISO 3450, AS2958.1, CAN-CSA424.30-M90

- Cab

- ISO 3449, SAE J231, AS2294.3, EN13627

- Cab

- ISO 3471, SAE J1040, AS2294.2, EN13510

-

ELECTRICAL

- Alternator, 75-amp

- Receptacle group, auxiliary start

- Battery Disconnect Switch, Ground Level

- Starter, electric, 24-volt

- Diagnostic Connector

- Engine Shutdown Switch

- Lighting:

– External, front, rear

– Stop, single - Batteries, low maintenance

- Alarm, reversing

- Starting and Charging System

-

TIRES, RIMS, AND WHEELS

- Rims:

– Tubeless, set of four - Tires must be selected from the Mandatory Attachments section, choose between:

– Tire, 17.5 × R25 VSMS L5S Bridgestone

– Tire, 17.5 × R25, VSDL Bridgestone

- Rims:

-

OPERATOR ENVIRONMENT

- Caterpillar Electronic Monitoring System (CEMS), (dash instrument panels)

- Horns, electric

- Instrumentation/gauges:

– Speedometer/tachometer

– Fuel level

– Hydraulic oil temperature

– Engine coolant temperature - Light, warning, residual brake

- Pilot Hydraulic Implement Controls, Single Joystick

- Cab, ROPS and/or FOPS certified

- Steering and Transmission Integrated Control (STIC™) Steering

- Seat, Suspension Tee with retractable seat belt

-

POWER TRAIN

- Engine:

– Cat 3306B six cylinder, diesel

– DITA (Direct Injection, Turbocharged, Aftercooled) - Precleaner, engine air intake

- Fuel Priming Aid

- Brakes, full hydraulic enclosed wet multiple-disc (SAFR)

- Heat Shields

- Torque Converter

- Transmission Neutralizer

- Transmission, automatic planetary power shift (4F/4R)

- Engine:

-

OTHER STANDARD EQUIPMENT

- Guards, engine and transmission

- Bucket Dump (3.1 m3/4.1 yd3)

- Catalytic Exhaust Purifier/Muffler

- Cap, Radiator Manual Release

- Decals, International Picto Graphics

- Service oil sample

- Fenders, Front, Rear

- Firewall

- Handholds

- Hydraulic Oil Cooler, Swing Out

- Valve, drain, transmission oil filter

- Protection bars, rear frame

- Radiator Grill, Swing Out

-

TIRES, RIMS, AND WHEELS

- Rims:

– Tube, set of four

– Spare (Tube or Tubeless)

– Rim Identification Numbering

- Rims:

-

OPTIONAL EQUIPMENT

- After-Treatment Options

– DPF (Flow Through) - Brake Release Arrangements, Includes Steering Release

– Recovery Hook

– Recovery Bar - Bucket:

– Cutting Edge, Bolt-On

– Cutting Edge, Cat Weld On

– Heel Shrouds, Ejector and Dump Buckets

– Lip Fully Welded or Tack Welded

– Mechanically Attached Wear Plate System (MAWPS)

– Various Sizes, Dump (2.5 m3/3.2 yd3, 2.8 m3/3.7 yd3, 3.4 m3/4.4 yd3), Ejector (2.4 m3/3.1 yd3)

– Standard Lip or Bolt-On Lip

– Wear Bars, Ejector and Dump Buckets

– Wear Liner - Covers:

– Guard, for lift arm and front frame lights

– Rear Grill (Additional Bolt-On Guard) - Draw Bar Attachment, Bolt-On

- Fast Fill System:

– Coolant

– Engine Oil

– Fuel

– Hydraulic Oil

– Transmission Oil - Fluids

– Arctic Fuel

– Arctic Coolant - Lifting Group, Mine Transfer

- Lubrication System

– Automatic

– Centralized - Operators Station ROPS/FOPS Enclosed

– Air Conditioning

– Cab Pressurizer and Filter

– Dome Light

– Door Strut

– Heater

– Radio Ready Compartment for Radio and Speakers

– Wiper Control, Intermittent - Park Brake Automatic Activation

- Park Brake Switch Engagement

– Push to Apply

– Pull to Apply - Reflective Tape

- Remote Control Interface (excludes Transmitter and Receiver), Includes Warning Lights (Green)

– Cattron

– RCT - Reversible Steering

- Ride Control System

- Rim

– Tube Type

– Tube or Tubeless (chain ready)

– Spare (Tube or Tubeless)

– Rim Identification Numbering - Secondary Steering System

- Service Tools

– Recovery Bar (for use with Brake Release, Recovery Bar System)

– Reference Parts Manual for Additional Tooling Available - Switches

– Idle Timer

– Lift Arm Positioner

– Transmission Neutralizer Override Switch

– Transmission Pressure ABA Park Brake Engagement

- After-Treatment Options

-

OPERATOR ENVIRONMENT

- Operator's Station ROPS/FOPS Enclosed:

– Air Conditioning

– Cab Pressurizer and Filter

– Dome Light

– Door Strut

– Heater

– Radio Ready Compartment for Radio and Speakers

– Wiper Control, Intermittent - Instrumentation/gauges:

– Brake pressures - Secondary Steering System

- Operator's Station ROPS/FOPS Enclosed:

-

POWER TRAIN

- Engine:

– After-Treatment Options – DPF (Flow Through) - Reversible Steering

- Park Brake Automatic Activation

- Park Brake Switch Engagement – Push to Apply/Pull to Apply

- Radiator, High Efficiency

- Engine:

-

$315,000 2022 Cat 330-07

-

$315,000 2022 Cat 33007

-

$299,900 2021 Cat 330-07

-

$100,000 2019 Cat 972MXE

-

$99,950 2017 Cat CS44B

-

Browse All Used Equipment Inventory

View More

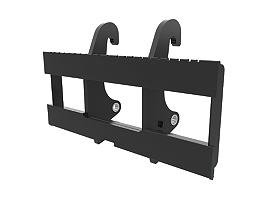

Forks: 1524mm (60in) Log & Lumber Fork; Fusion™

Forks: 1524mm (60in) Log & Lumber Fork; Fusion™  Forks: 2298mm (90in) Logging Forks

Forks: 2298mm (90in) Logging Forks  Forks: 1566 mm (62 in) Pallet Fork Carriage

Forks: 1566 mm (62 in) Pallet Fork Carriage  Forks: 1550 mm (61 in) Pallet Fork Carriage

Forks: 1550 mm (61 in) Pallet Fork Carriage