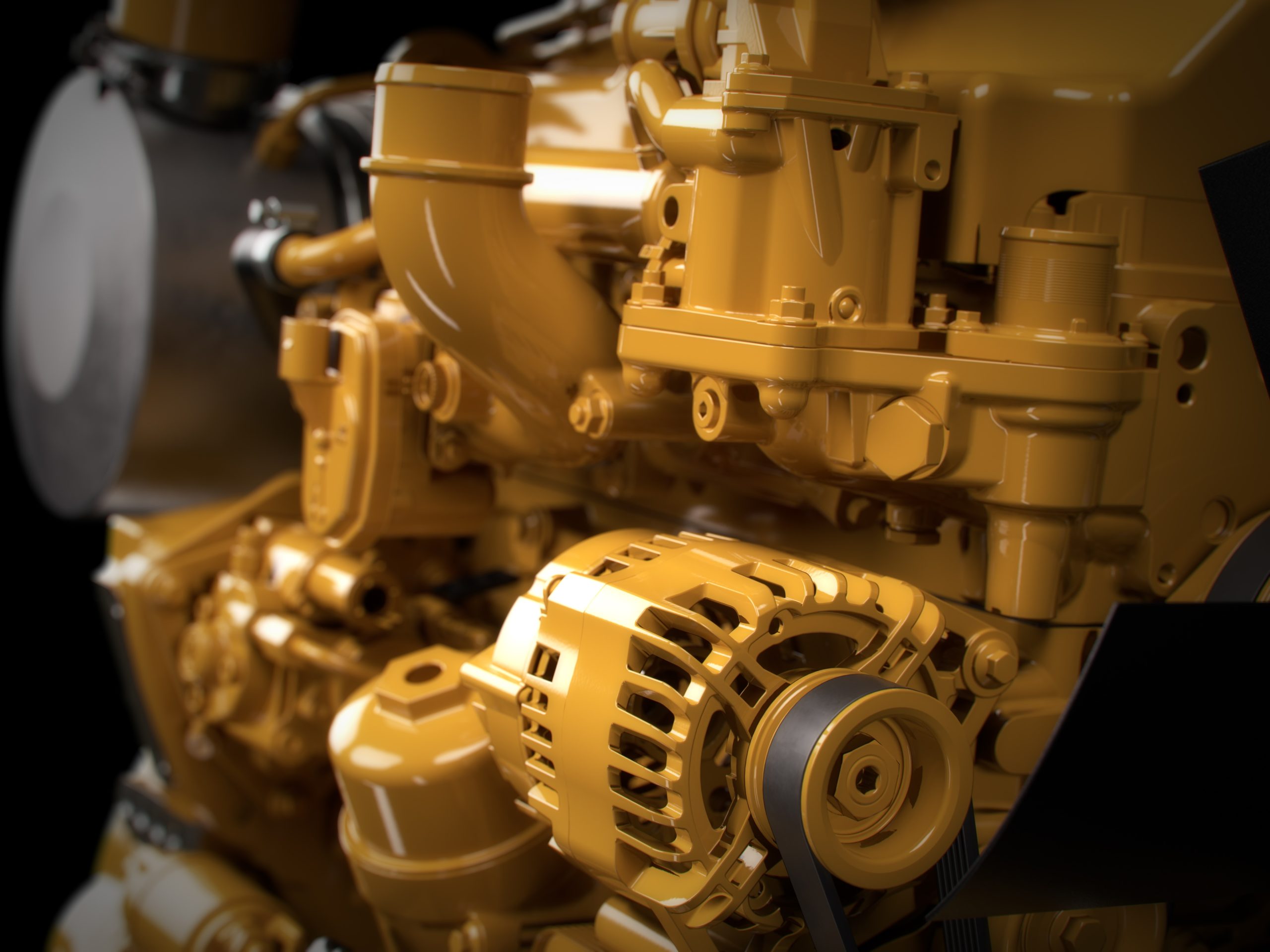

Caterpillar manufactures parts for various ground conditions, from soft and wet terrain to rocky and abrasive surfaces. Each design considers ground pressure, load distribution, surface density and other related factors.

With every hour of operation, your machine’s undercarriage is put to the test. When undercarriage components wear out or fail unexpectedly, the costs go beyond parts replacement — you face expensive downtime and lost productivity. Choosing genuine Cat® components for all your maintenance needs helps solve these challenges with long-lasting performance.

At Foley, Inc., we understand how undercarriage performance can impact your company’s bottom line. We offer a huge inventory of undercarriage replacement parts compatible with all Cat equipment with undercarriages. From dozers and skid steers to excavators and track loaders. Our parts specialists can help you select the right components based on your model’s specifications.

Choosing the right undercarriage components and scheduling timely replacement helps prevent premature wear while extending the service life of your equipment. We stock a complete selection of genuine Cat undercarriage parts to serve clients throughout New Jersey, eastern Pennsylvania, northern Delaware and Staten Island. Our inventory includes options for every machine type and operating condition, from standard-duty components to severe-service solutions for high-impact and abrasive environments.

For cost-conscious budgets, we offer quality-tested used components and remanufactured parts when available. Each part undergoes thorough inspections and testing to verify performance.

Examples of common undercarriage parts include:

Caterpillar designs and tests undercarriage components as complete systems instead of individual parts. Each Cat part works together to distribute stress evenly and achieve balanced wear throughout the undercarriage.

Other benefits of choosing parts from Caterpillar include:

Caterpillar manufactures parts for various ground conditions, from soft and wet terrain to rocky and abrasive surfaces. Each design considers ground pressure, load distribution, surface density and other related factors.

Heat-treated steel and premium-grade materials help extend service life. Each component undergoes strict testing to ensure peak performance in challenging environments.

Cat components work together to maintain the proper tension and alignment throughout the undercarriage. This compatibility helps reduce power loss and maintain track life while minimizing strain on other machine systems.

Genuine parts help optimize machine stability and traction while increasing productivity and reducing operating costs.

At Foley, Inc., our experts understand how your application and the area’s terrain impact component selection. We can help you choose the most practical and cost-effective options for your machine. Our extensive inventory ensures quick access to the undercarriage components you need, with most parts available within 24 hours.

Daily deliveries to our locations and parts drops help streamline availability across our service area. For direct shipping and expedited deliveries, visit parts.Cat.com. For assistance over the phone, you can call our Piscataway Campus at 732-885-3090 or our Bensalem campus at 215-245-2777.

You can also stop by any of our locations for personalized attention.

Don’t let worn or mismatched undercarriage components affect your heavy equipment’s performance and reliability. Get in touch with us today if you have any questions.

Shop Undercarriage