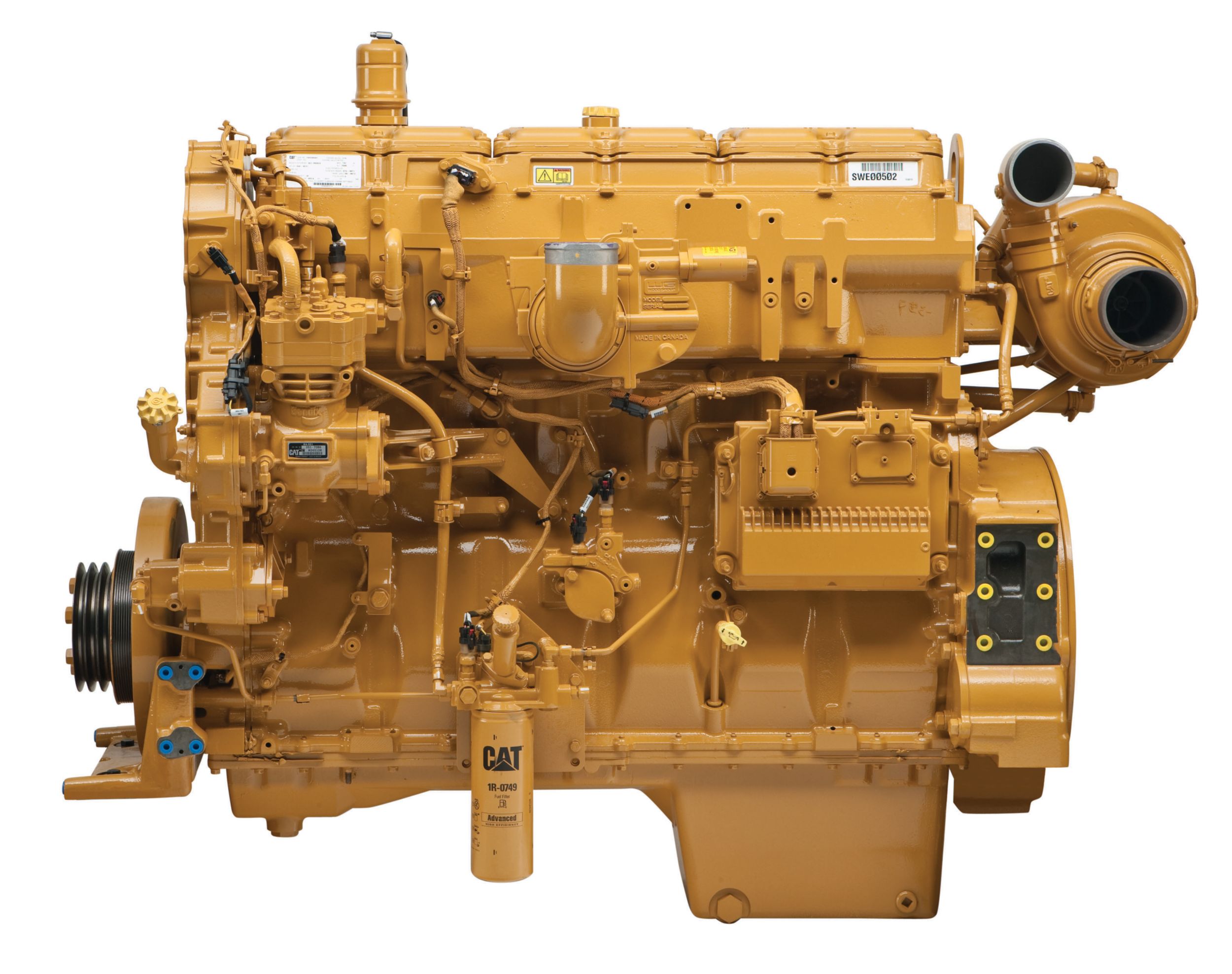

Minimum Rating

440BHP

Maximum Rating

595BHP

Emissions

EPA and CARB Non-Road Mobile Tier 3, EU Stage IIIA

Rated Speed

2100r/min

Bore

5.4in

Stroke

6.75in

Displacement

928in³

Aspiration

Turbocharged-Aftercooled

Governor and Protection

ADEM A3

Engine Weight - Net Dry

2743lb

Rotation from Flywheel End

Counterclockwise

Oil Change Interval

250

Flywheel and Flywheel Housing

SAE No. 0 or SAE No. 1

Flywheel Teeth

136 (SAE 0), 113 (SAE 1)