Maximum Rating

2500BHP

Displacement

3596in³

Minimum Rating

2250BHP

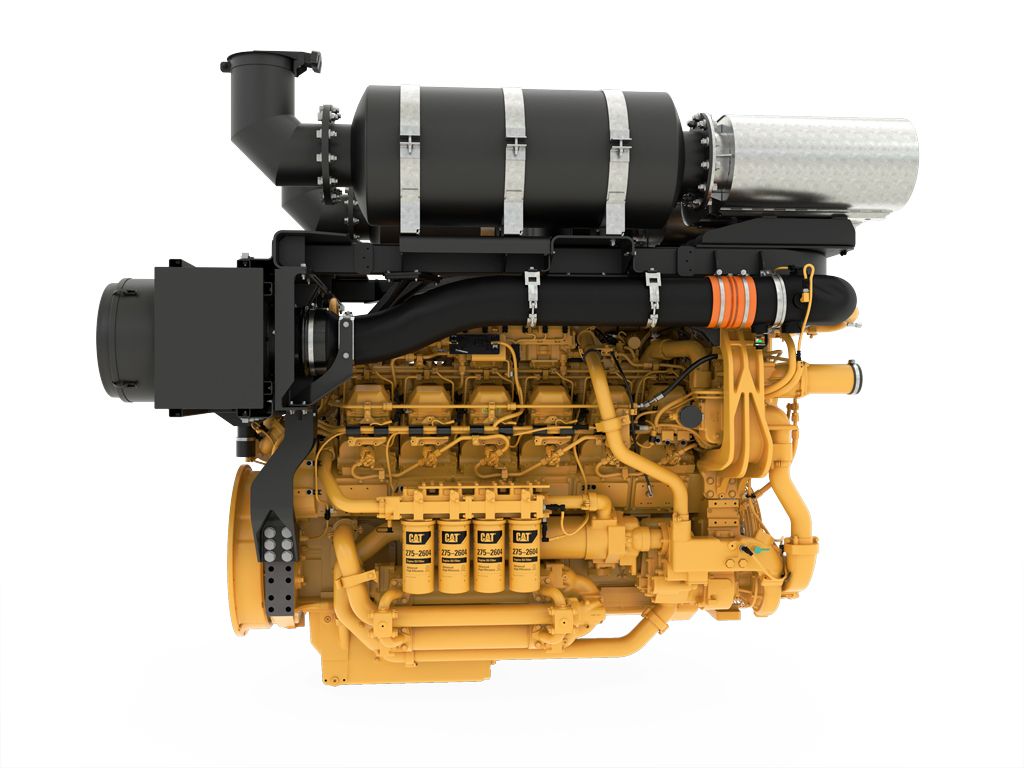

Aspiration

SCAC and ATAAC

Flywheel and Flywheel Housing

SAE No. 0

Flywheel Teeth

151

Stroke

8.5in

Bore

6.7in

Governor and Protection

™ A5) / DGB System (ADEM™ A6)"

data-metric="">

Electronic (ADEM™ A5) / DGB System (ADEM™ A6)

Rotation from Flywheel End

Counterclockwise